R&D case: Stainless steel cold forging

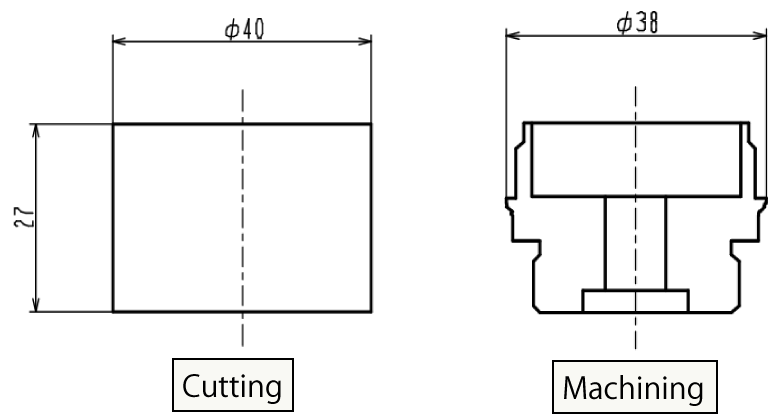

Conventional method

■Customer issues of conventional method

- ・Material yield is poor ⇒ 40%

- ・Low production capacity ⇒ 100-300pcs/month

- ・Total cycle of cutting and machining is long. ⇒ parts cost is high

New technology /new method

■Effects of new technology /new method

- ・With cold forging technology (NNS) Near Net Shape is possible and which increases material yield ⇒ improves by 35%

- ・Near net shape reduces the cycle time and production capacity is improved ⇒ By 300%

- ・Decrease in material loss and processing time leads to cost reduction.⇒ By 28%

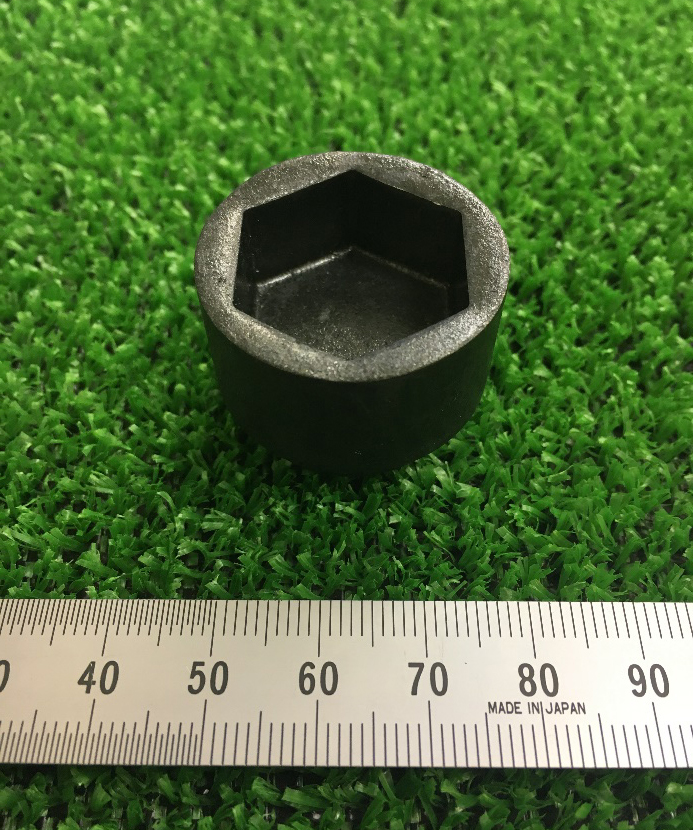

Examples of stainless steel Cold forged products

1.Valve parts cold forging example

2.Materials for which forging evaluation has been completed

- ・SUS304

- ・SUS316

- ・SUS316L

- ・SUS430

3.Examples of other cold forged product of different shape

Please contact us for consulting, regardless of Evaluation and case.

Technology and Sales Section

TEL. +81-274-22-7003 / FAX. +81-274-22-7590